The wheels were badly oxidized. I sanded them starting with 220 grit paper and progressing up through 1500 grit before polishing. The wheels were then cleaned and painted with SEM Hot Rod Black.

hdscarbro

hdscarbro

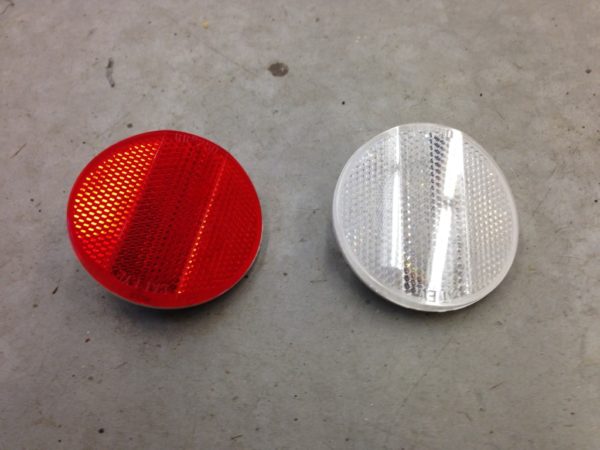

Mounting the Electrical Bits

With my SR250, I didn’t think about mounting the electrical components until the seat and tank were in place. This made mounting the components more difficult than it needed to be. For this bike, I’m getting this stuff sorted early.

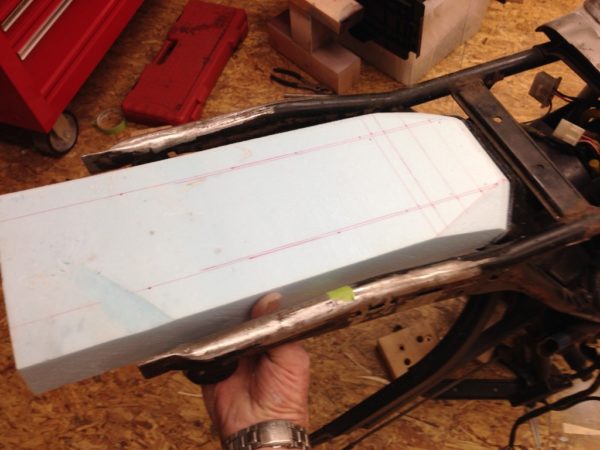

The stock rear fender didn’t fit under the seat and had a raised mounting spot for the fuse panel. I cut the stock fender back to allow a flat fender to be attached to it. It is low enough to allow the electrical bits to mounted it and fit beneath the seat.

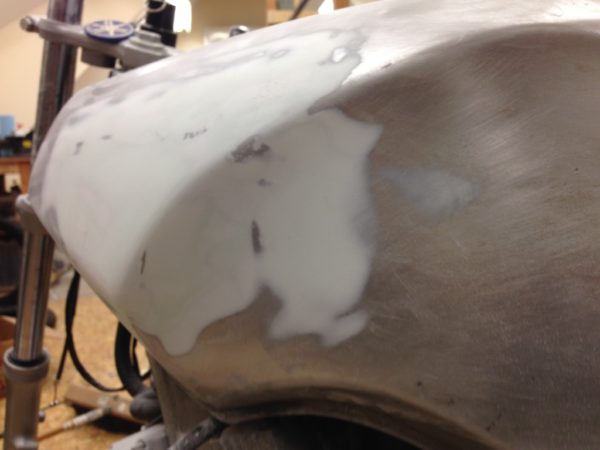

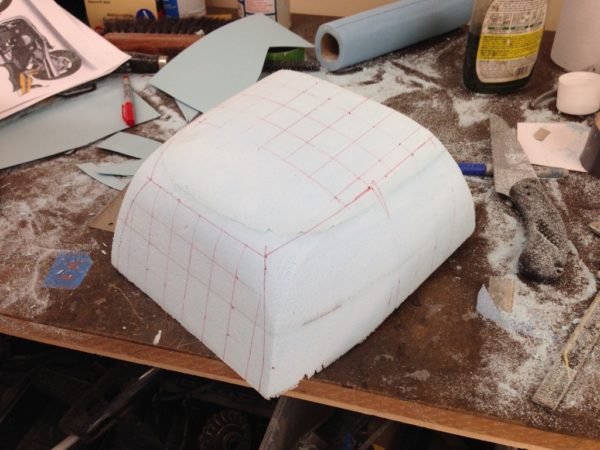

Seat

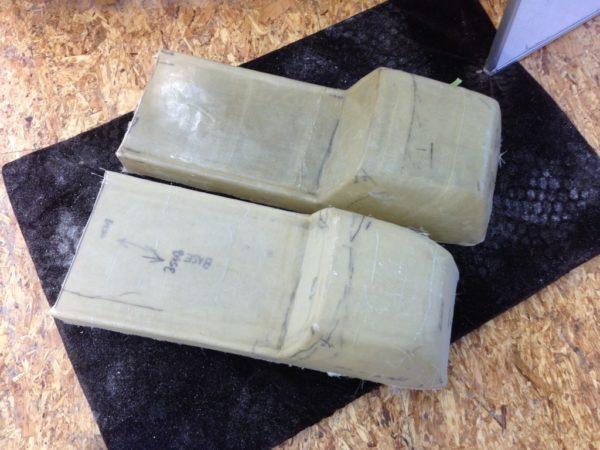

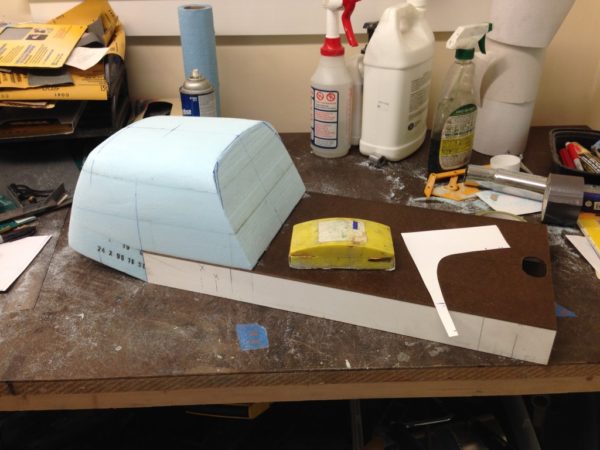

This is the second seat that I’ve made. For developing the shape, I’m using 2″ foundation foam from my local building supply. The foam is glued using spray styrofoam adhesive from a craft store. Regular spray adhesive dissolves styrofoam. The rough cuts are done by hand or on my bandsaw. All shaping is done with 60 grit sandpaper.